International Mountain Day was established in 2003 to raise global awareness of the ecological importance of mountainous areas and create opportunities for their sustainable development.

Recently, the hashtag called Protect Mountain Ecosystems trended widely, sparking a collective call from society: Mountains are vital ecological barriers that demand careful stewardship, and we must always hold profound respect for nature. Guided by this shared understanding, environmental standards for developing photovoltaic (PV) projects in mountainous areas have been further elevated.

Intertwined Challenges: Four Key Difficulties in Mountain PV Development

Design Complexity

Mountainous terrain is characterized by fragmentation, variable slopes, and overlapping distribution of ecologically sensitive zones and developable areas. This requires balancing three critical factors—power generation efficiency, structural safety, and ecological protection—all at once. Traditional standardized designs often fail to adapt to such complex conditions.

Manufacturing and Durability Hurdles

Extreme weather events (common in mountainous regions) put PV support structures to the test, particularly in terms of structural strength, stability, and corrosion resistance. Subpar support performance not only shortens service life but also risks secondary ecological disruption during maintenance.

Construction Difficulties

Undulating terrain and irregular land use in mountains mean traditional PV mounting require large-scale land leveling, which easily damages surface vegetation and soil structure. Limited installation space and improper construction practices further increase ecological risks.

Operational and Maintenance Challenges

Inaccessible mountainous locations drive up labor, material, and time costs for equipment inspections and maintenance. Frequent maintenance activities also accumulate over time, threatening the integrity of mountain ecosystems.

Solutions: Embracing the Principle of Minimal Ecological Intervention

01.Precision in Design

ESET SOLAR leverages its diverse product portfolio to meet the needs of various mountain PV projects:

The Flexible Three-Cable Support System uses cable-based structures and flexible anchoring, eliminating the need for large-scale foundation excavation and minimizing ground disturbance. Its triangular support design, combined with a dual-damping system, effectively withstands mountain winds, simplifying long-term maintenance.

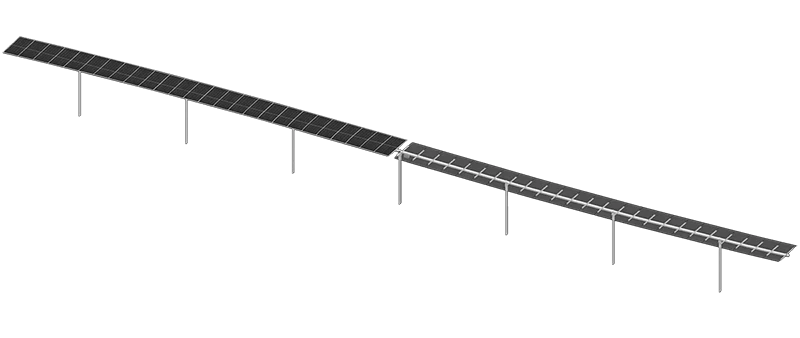

The ESEEK-Climber Support System—a single-row 1P independent PV tracking system—was developed under the concept of “adapting to hilly and mountainous terrain.” Its main beam socket gaps are designed to follow slope undulations, ensuring natural terrain fit. Telescopic tube connections and modular design significantly reduce on-site installation time, while controlled undulation at the main beam’s inflection points extends service life, cuts maintenance frequency, and lowers environmental impact.

For overall project solutions, a site-specific design approach is adopted:

Gentle areas use standardized PV mounting with shallow-buried foundations;

Steep slopes and rocky zones employ spiral ground piles with adjustable PV mounting;

Vegetation-dense areas deploy flexible PV mounting or high-leg PV mounting.

This approach ensures structural safety while minimizing ecological footprint and terrain modification.

02. Optimizing Performance

PV support systems use high-performance materials paired with advanced hot-dip galvanizing technology—boosting corrosion resistance several times compared to ordinary steel. This enables resistance to harsh mountain conditions, including high humidity, acid rain, and intense UV radiation.

Based on extensive experience in mountain PV projects, reinforced PV mounting (wind-resistance class ≥ Level 15) are installed in wind-prone areas. This guarantees structural stability during strong winds and heavy snow, extends equipment lifespan, and reduces the need for replacement due to material aging.

03. Low-Disturbance Construction

To address installation challenges:

PV support components (main beams, support structures, key connectors) are prefabricated as standardized modules in factories. On-site work is limited to assembly and calibration, significantly reducing on-site construction activity.

Slope-specific construction methods are applied: Small machinery is used for layered work on gentle slopes; manual assistance combined with lightweight equipment is deployed on steep slopes—minimizing concentrated disturbance to the ground surface.

Real-World Application: Advancing an Ecological Development Model

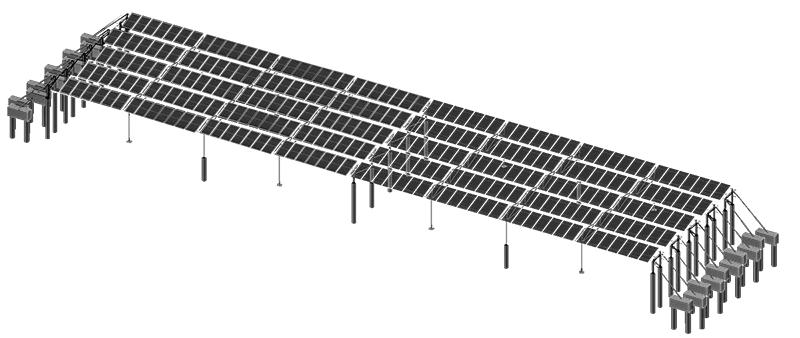

The core goal of mountain PV development is to achieve harmonious coexistence between clean energy production and ecosystem protection. This goal is fully demonstrated in ESET SOLAR’s Nagqu Gandan Kang Sang 120MW PV Project.

Located in a high-altitude, ecologically fragile area, the project uses precisely designed high-leg PV mounting (with a minimum height of over 1.5 meters from the ground). This design reserves space for vegetation growth beneath the PV panels, creating an integrated “PV power generation above, livestock grazing below” model. The project not only ensures stable annual power output but also sets a benchmark for eco-friendly development throughout the entire project lifecycle.

Wherever sunlight shines brightly on Earth, ESET SOLAR takes sunlight as its commitment and mountains as its witness. It safeguards the green ecology of mountainous regions, unlocks their vast potential for clean energy, and contributes to building a more sustainable home for our planet.